During my recent visit to Bukonzo Joint Cooperative Union (BJCU), located in Kasese District, Western Region of Uganda, I had the opportunity to visit Karughabira, one of BJCU’s 39 micro Washing Stations.

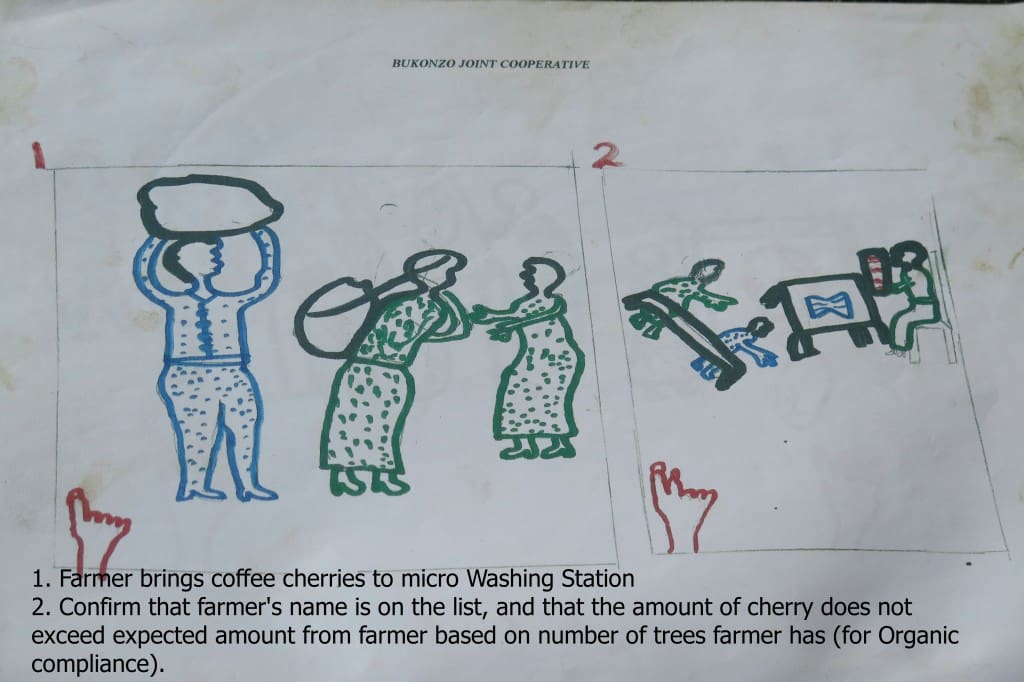

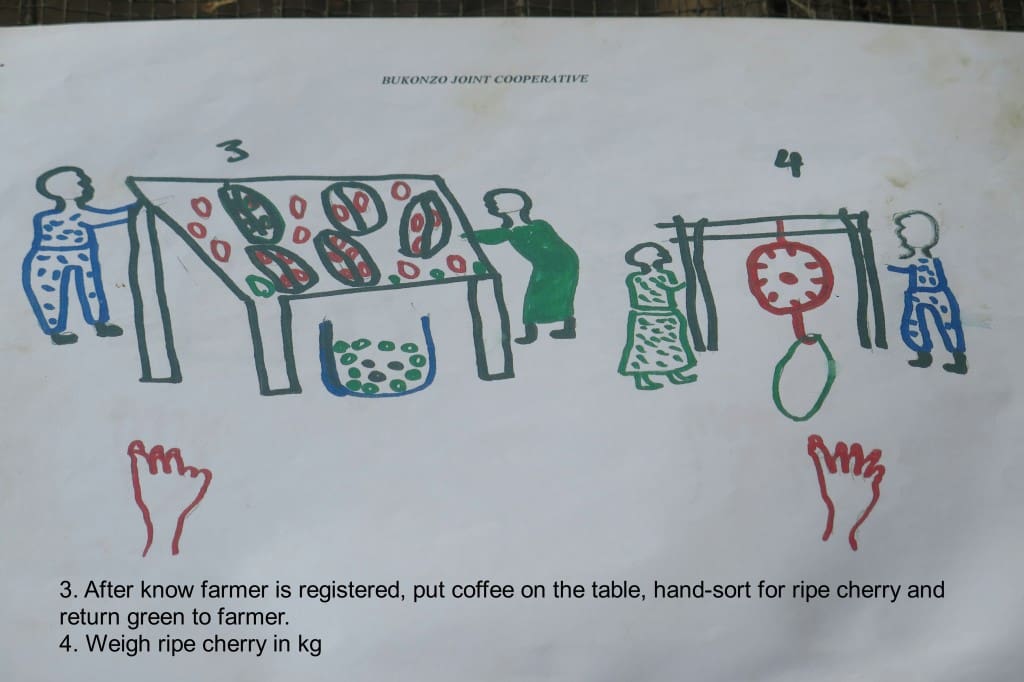

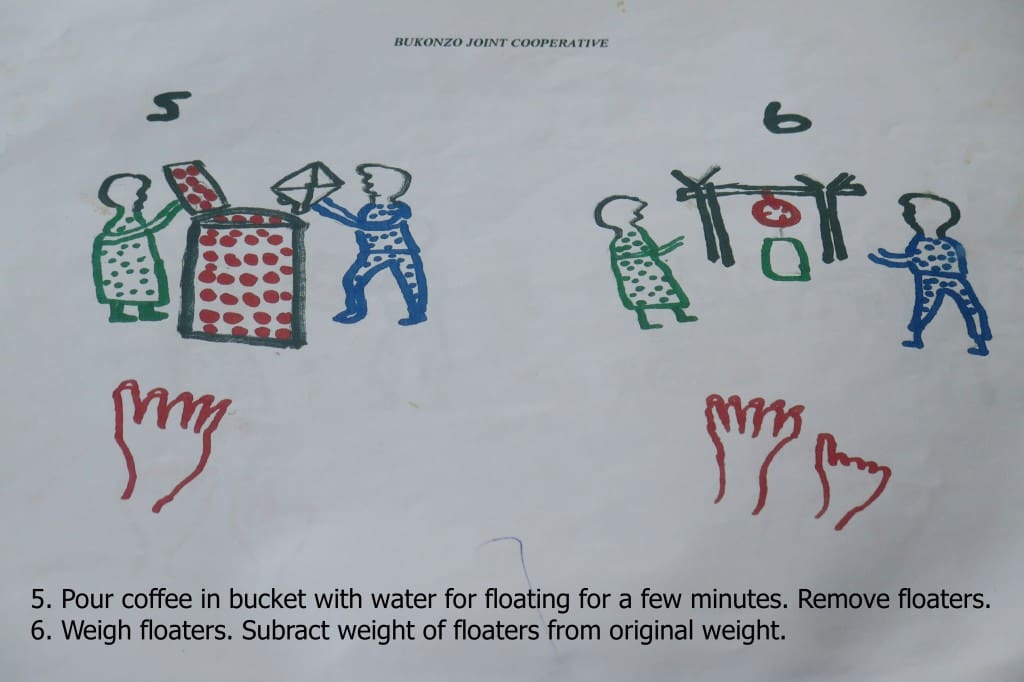

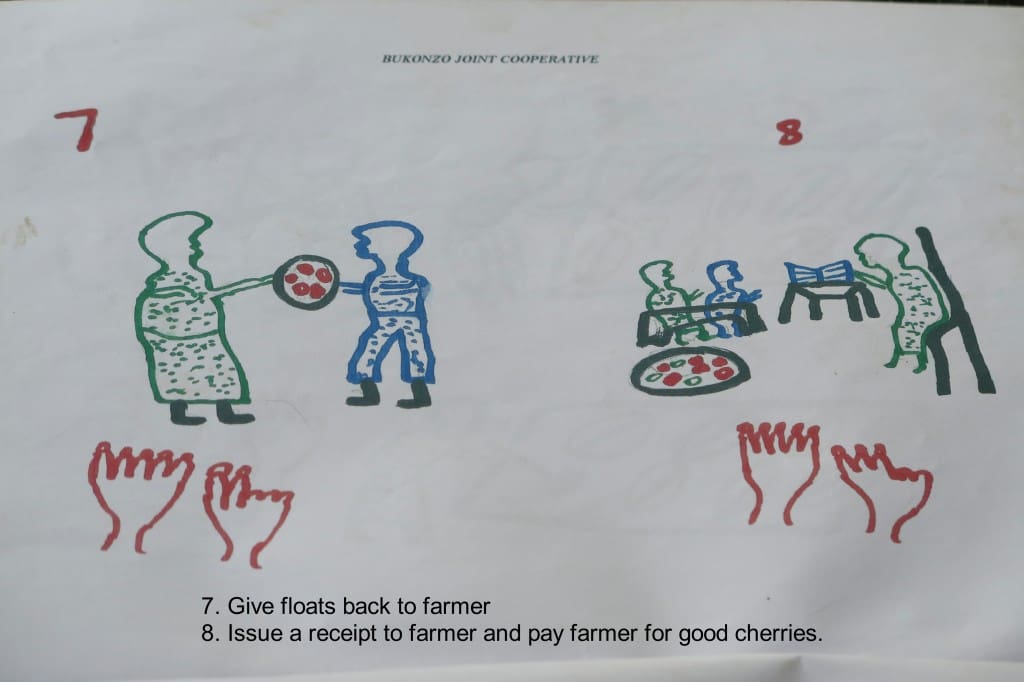

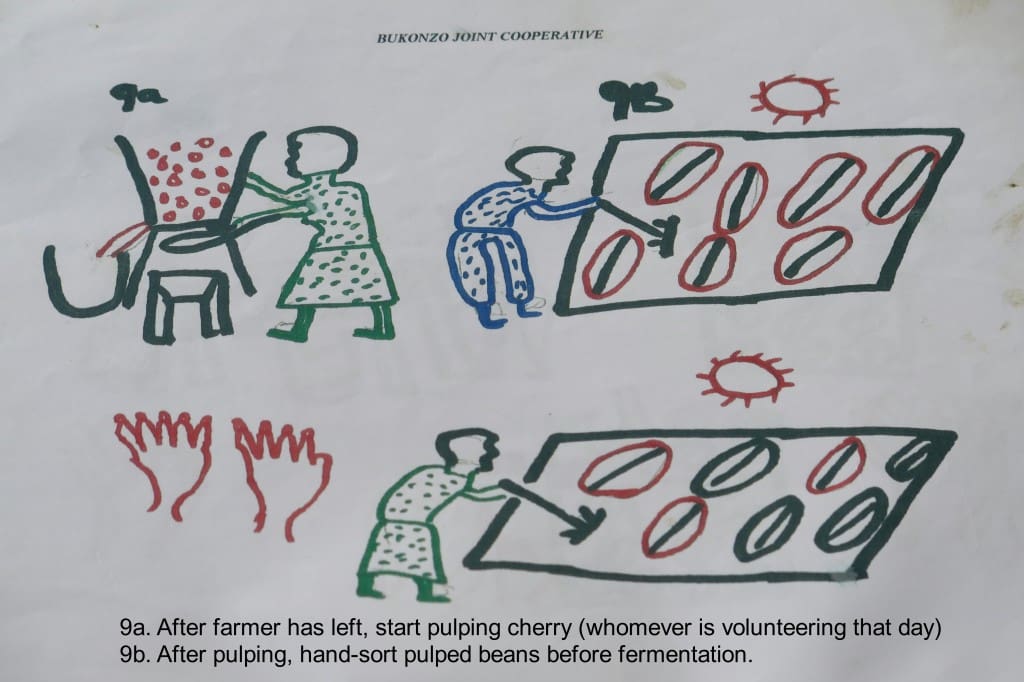

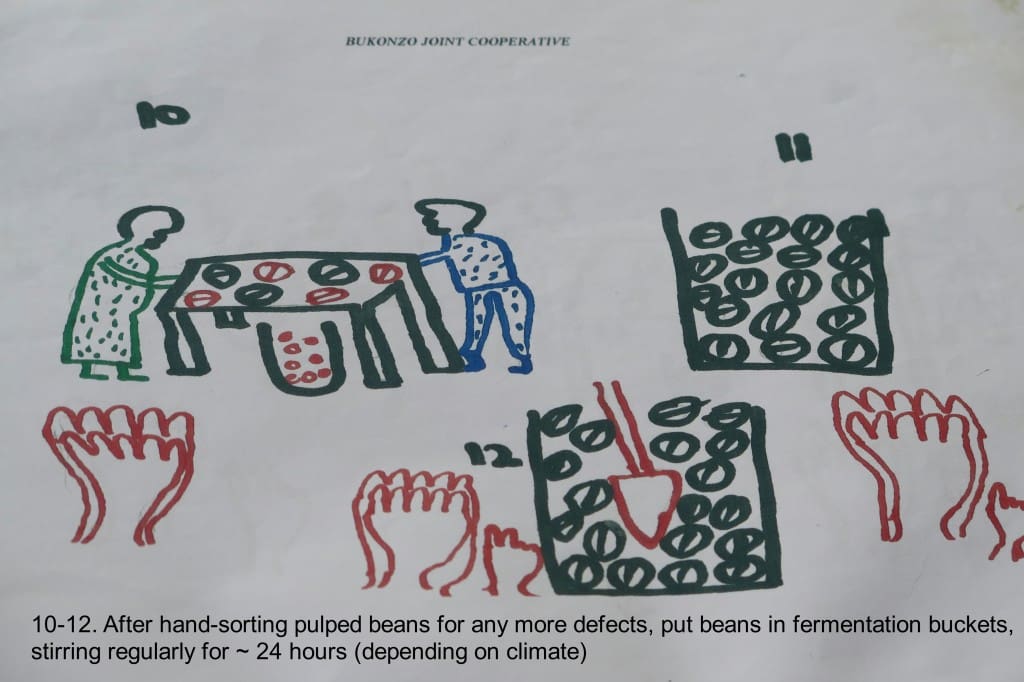

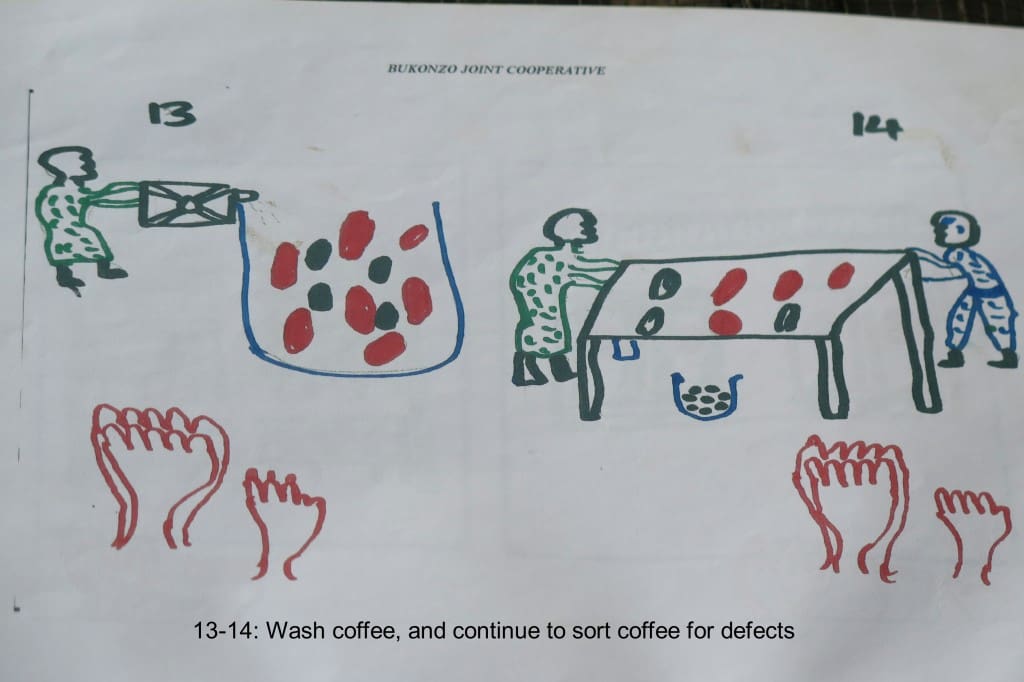

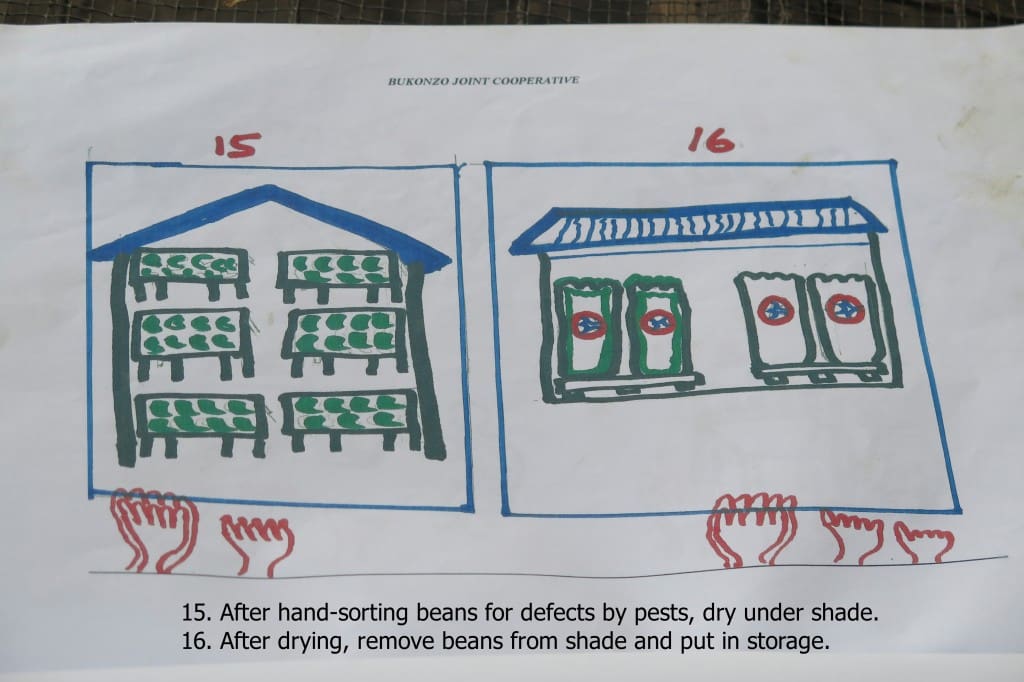

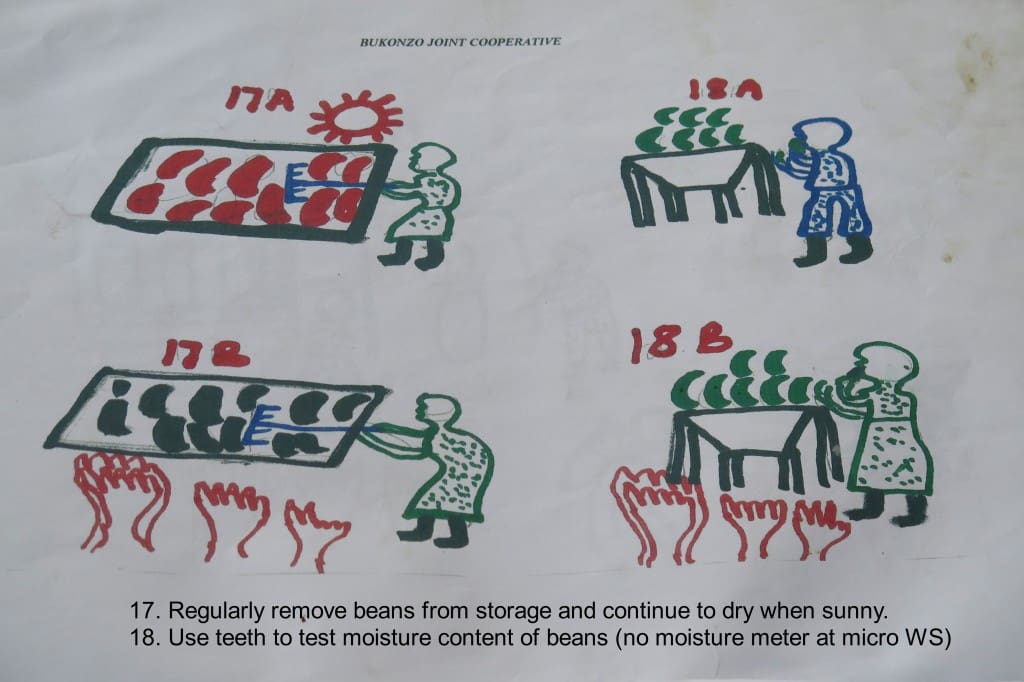

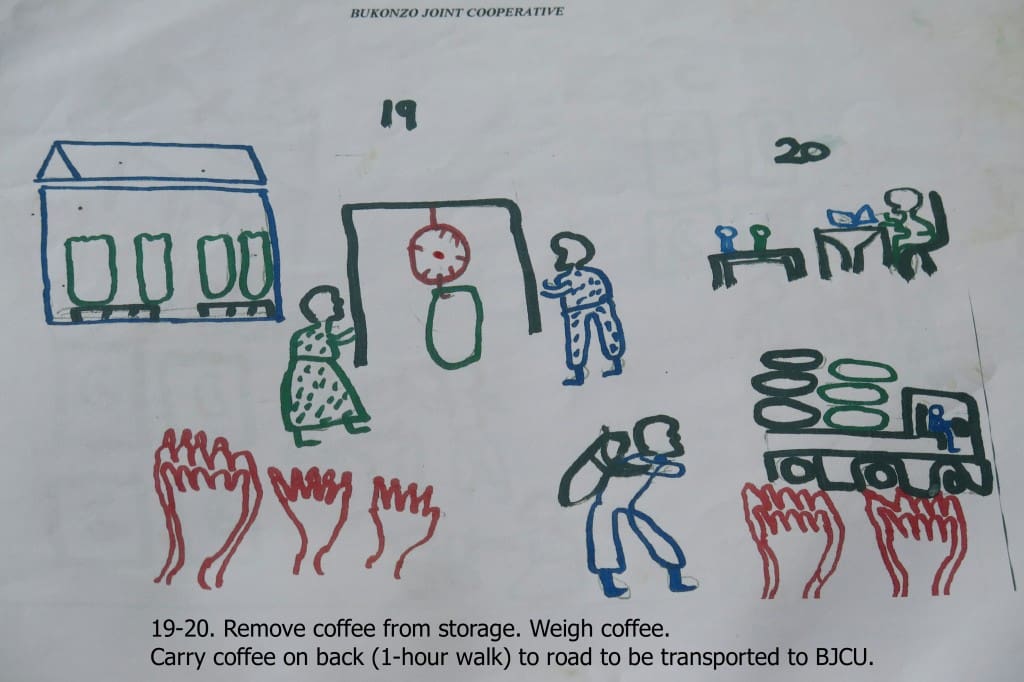

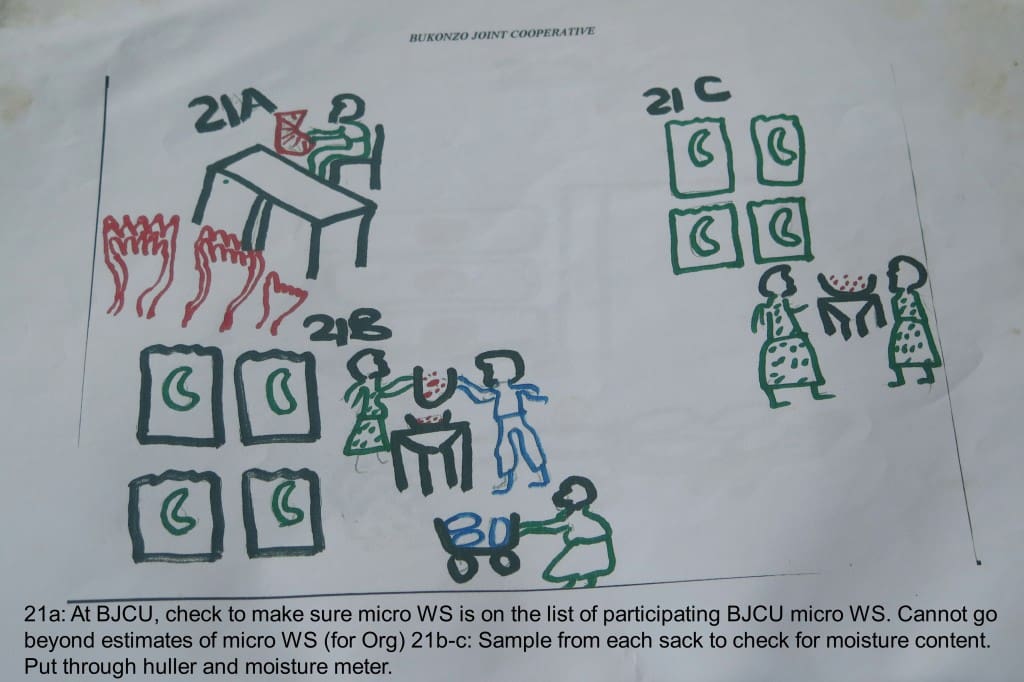

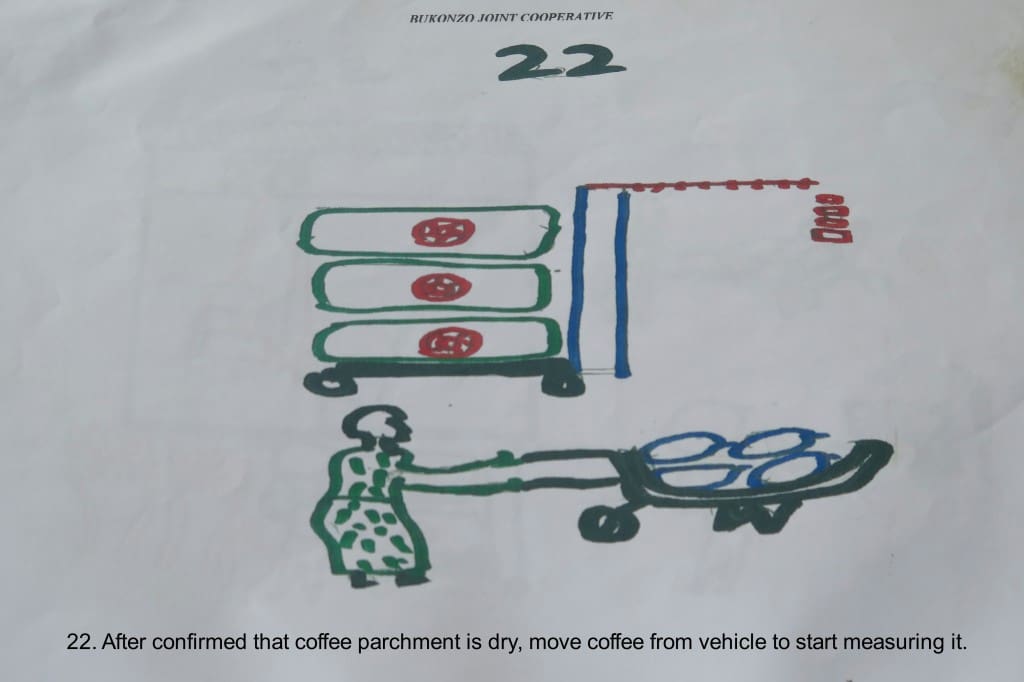

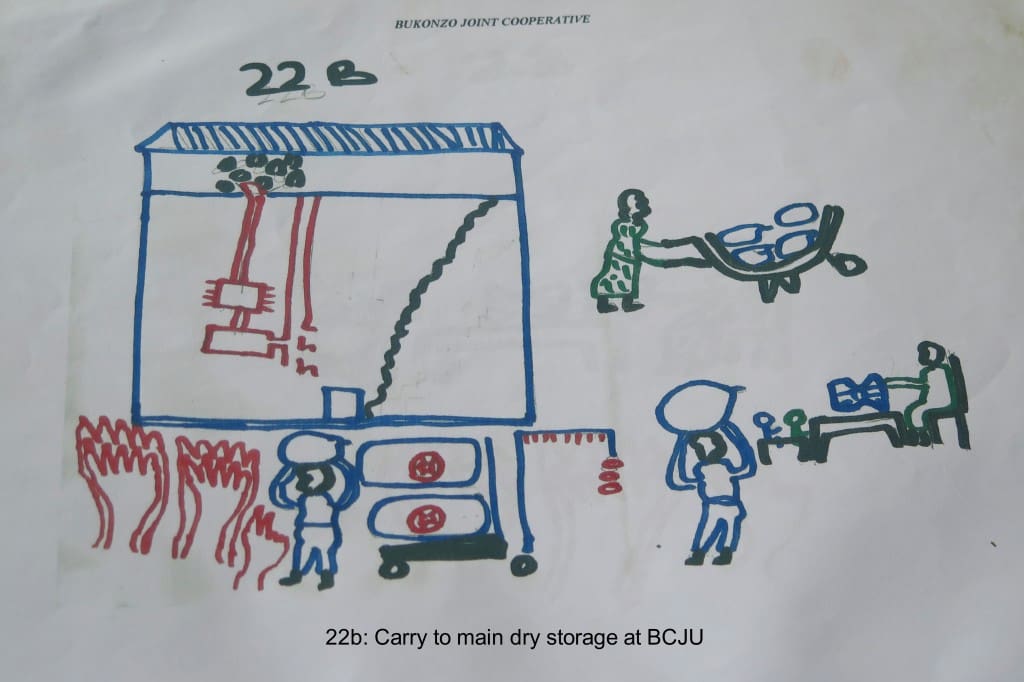

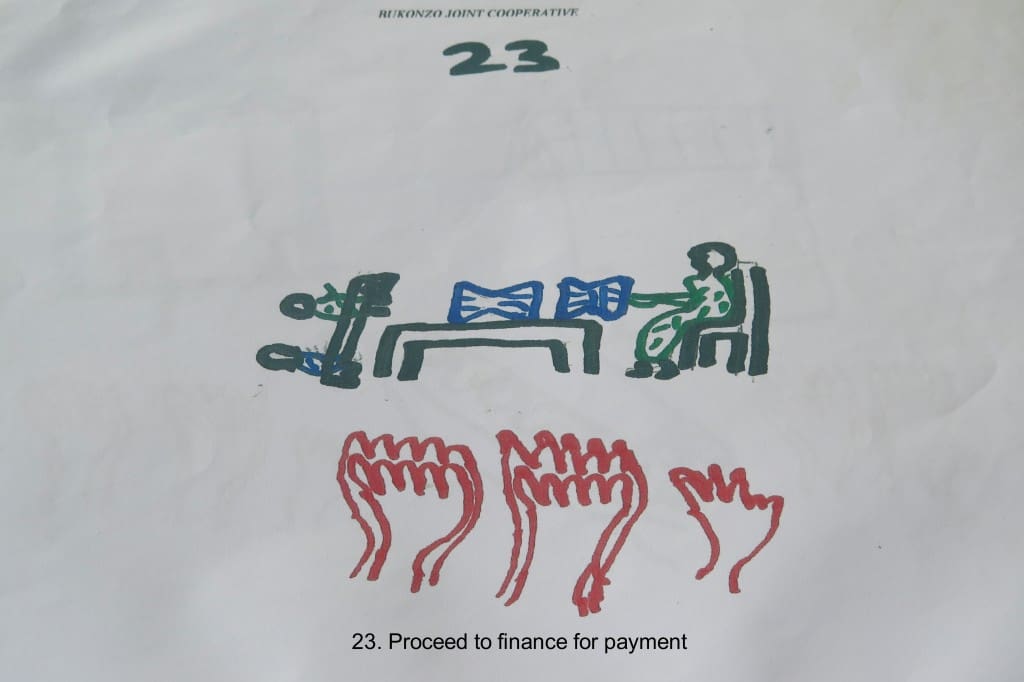

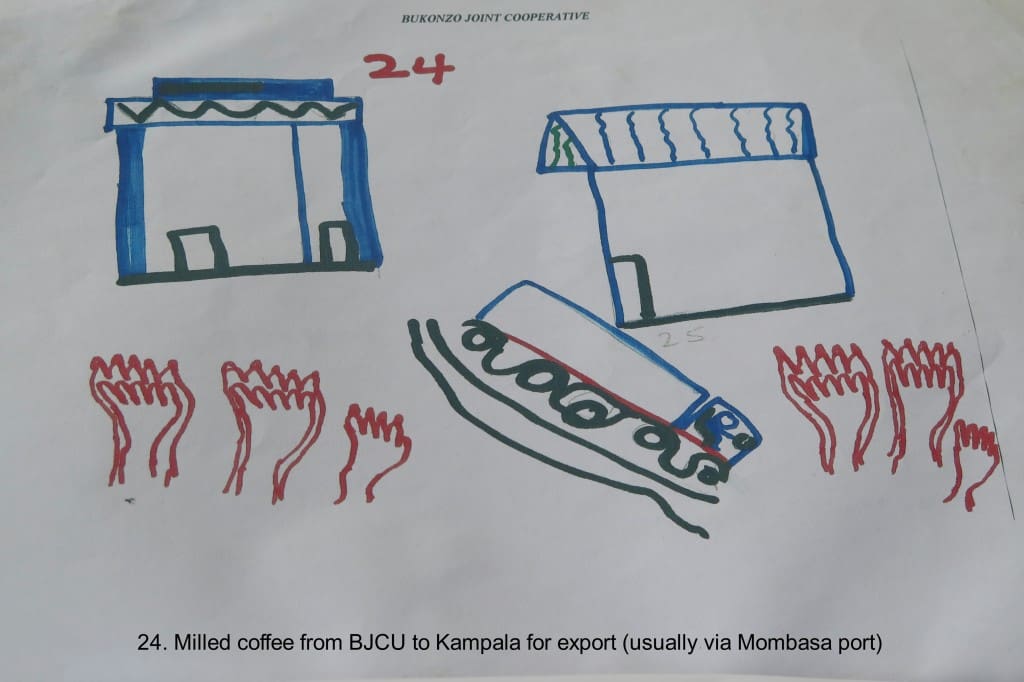

After driving for an hour and hiking for an additional hour on a narrow, steep path, we arrived at the washing station and were greeted by Thembo Yokoniya, the manager, and two additional female members of the cooperative. We spent some time discussing the basic details of their washing station (it was established in 2012; currently has 156 members, and an annual production of 26,000 kg of parchment; they have a small collective plot of 280 trees; their main genetic varieties are SL14 and SL28). Then they walked me through their step-by-step process, accomplished by using pictures, of processing cherry from farm to export. As we sat on a remote hillside and I listened to each of their steps, I was reminded of the amount of work that goes into bringing each and every ripe cherry to export. I hope you enjoy this step-by-step manual as much as I did. Please scroll through pictures below (I have added captions to the steps for clarification).